Rapid Prototyping

Profile and Objective

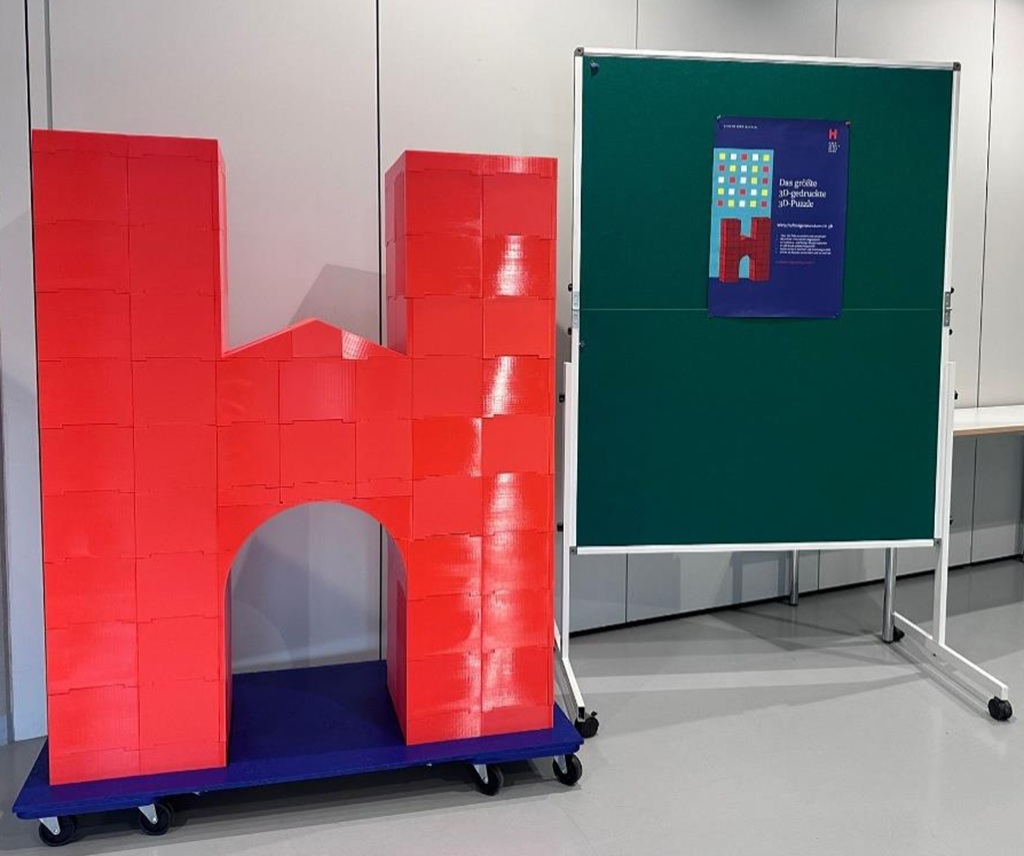

The technology of additive manufacturing has developed rapidly in recent years. A wide variety of materials can now be used to manufacture components. In this process, the materials are manufactured without tools from a CAD data set using different, material-dependent processes. Additive manufacturing is used to create prototypes (rapid prototyping), to manufacture tools (rapid tooling) or to directly produce components (rapid manufacturing).

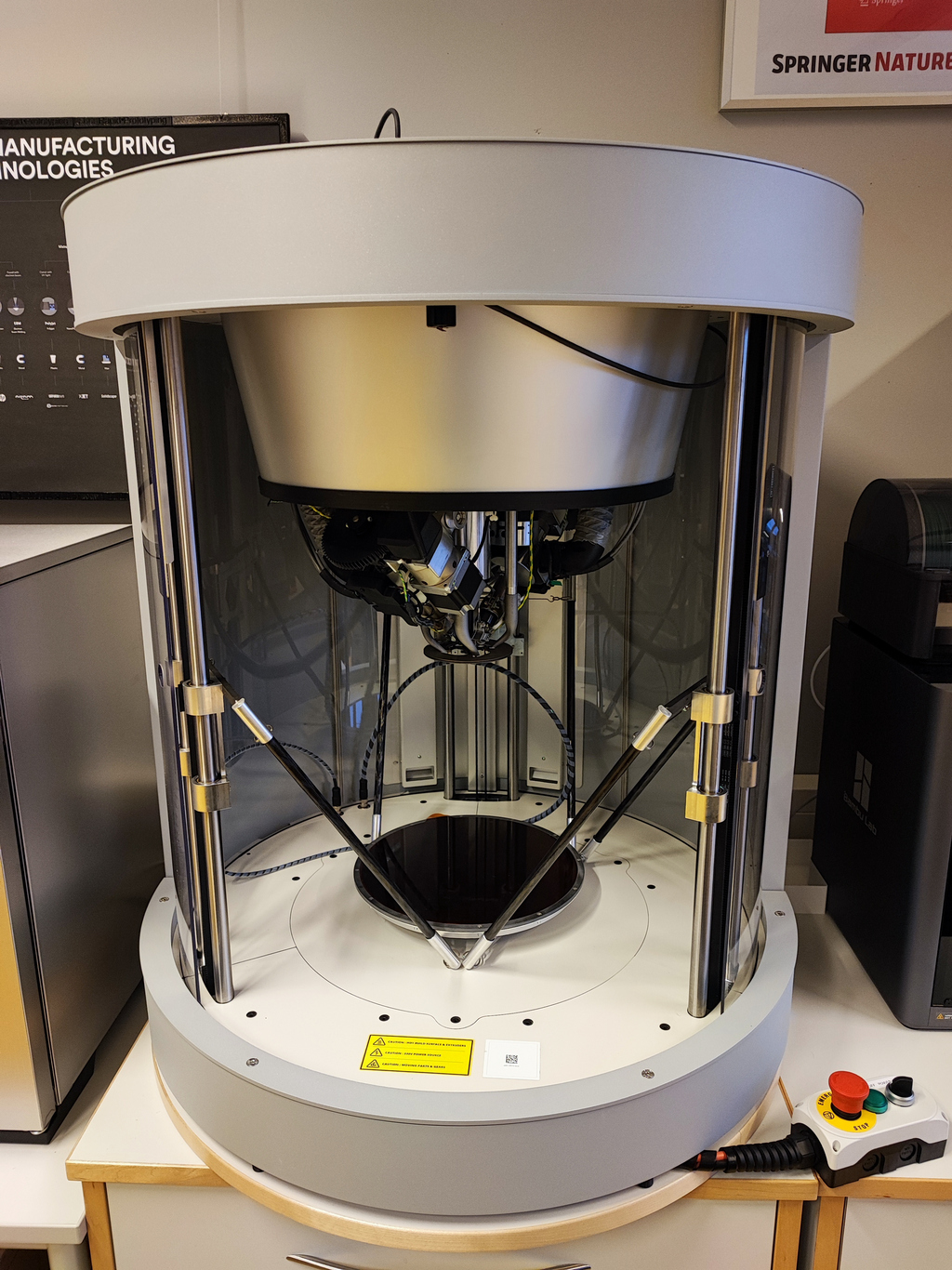

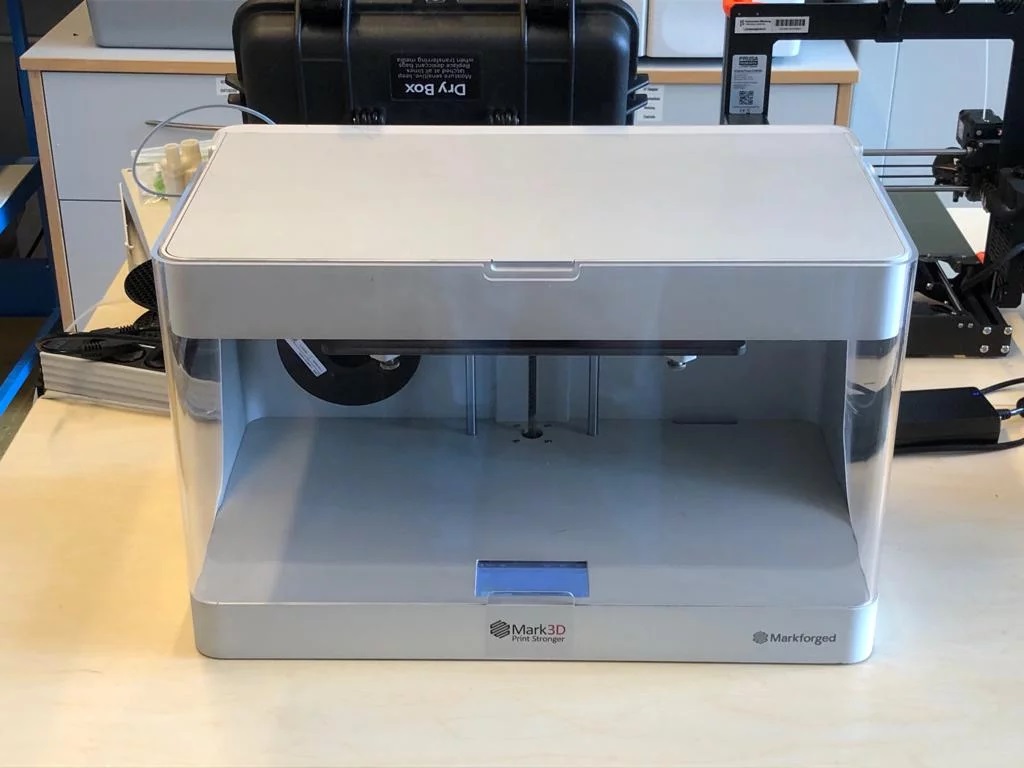

Various advanced 3D printers and 3D scanners are available in the Rapid Prototyping laboratory at Offenburg University of Applied Sciences. In addition to their use in teaching and research, these are used to produce individual parts for university or student projects, such as for the Sweaty robot. In addition, printing jobs for external interested parties are also accepted upon request and after consultation with the lab staff.

If you are interested in 3D printing, you can find more information in the tab "further information".

We hope you enjoy visiting our laboratory page!

Hardware:

- 3D-printer with continuous fiber reinforcement MarkTwo from Markforged

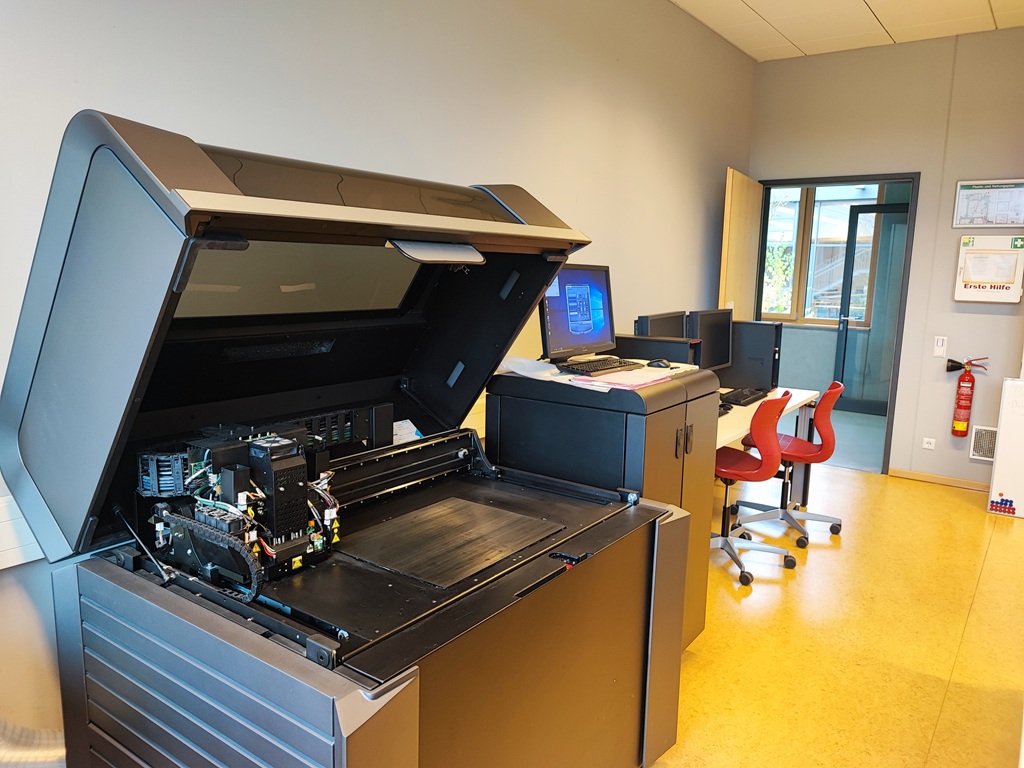

- Multimaterial printer J750 from Stratasys

- ProJet 660 Pro from 3D Systems

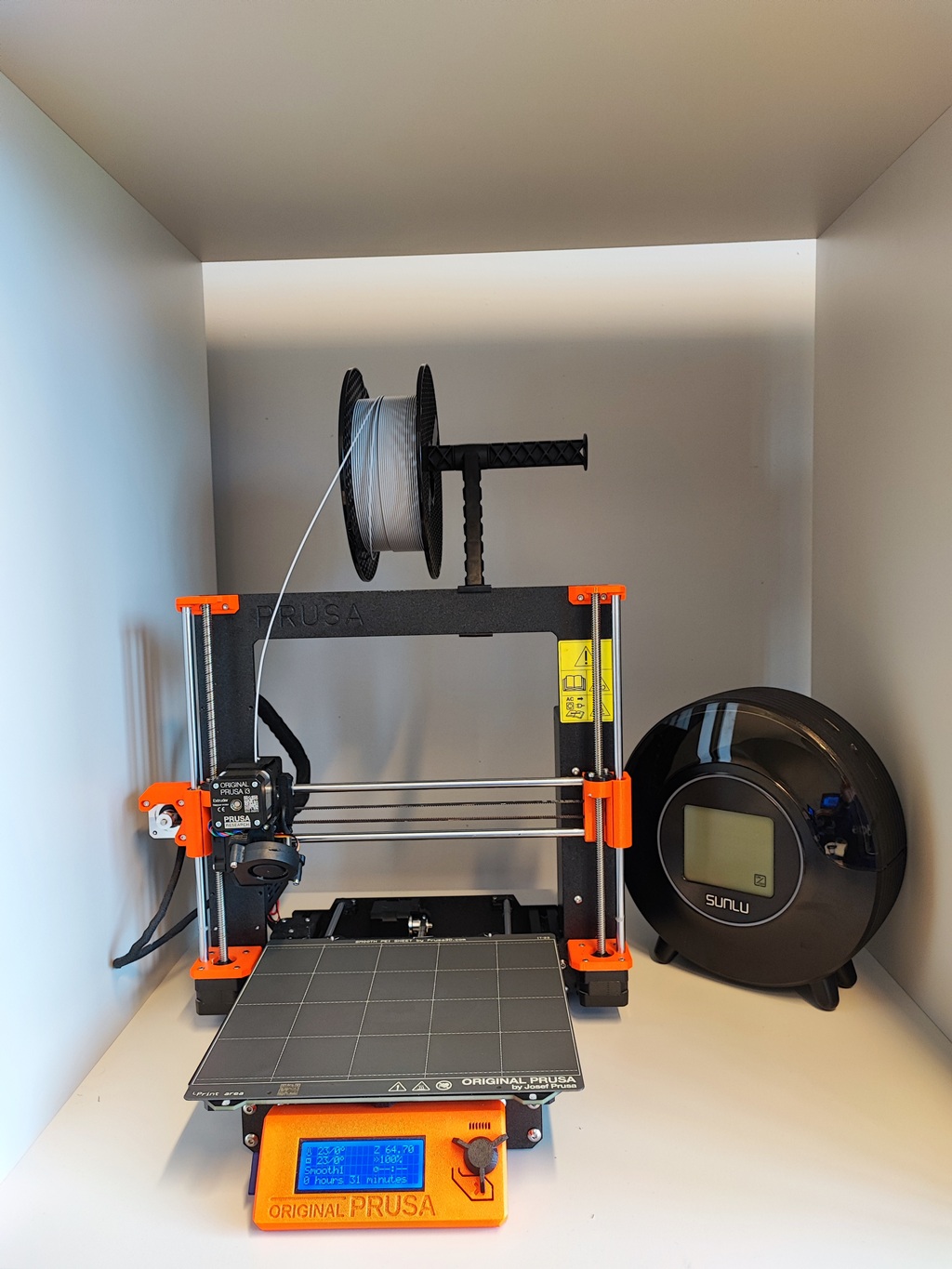

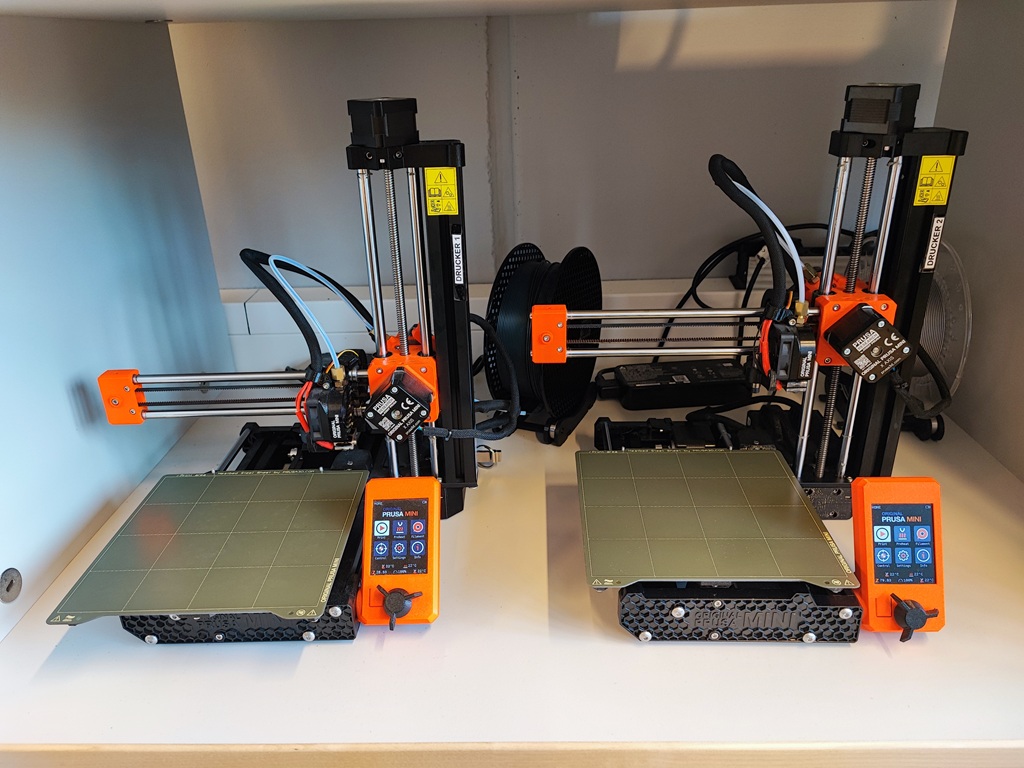

- MINI+ from Prusa Research

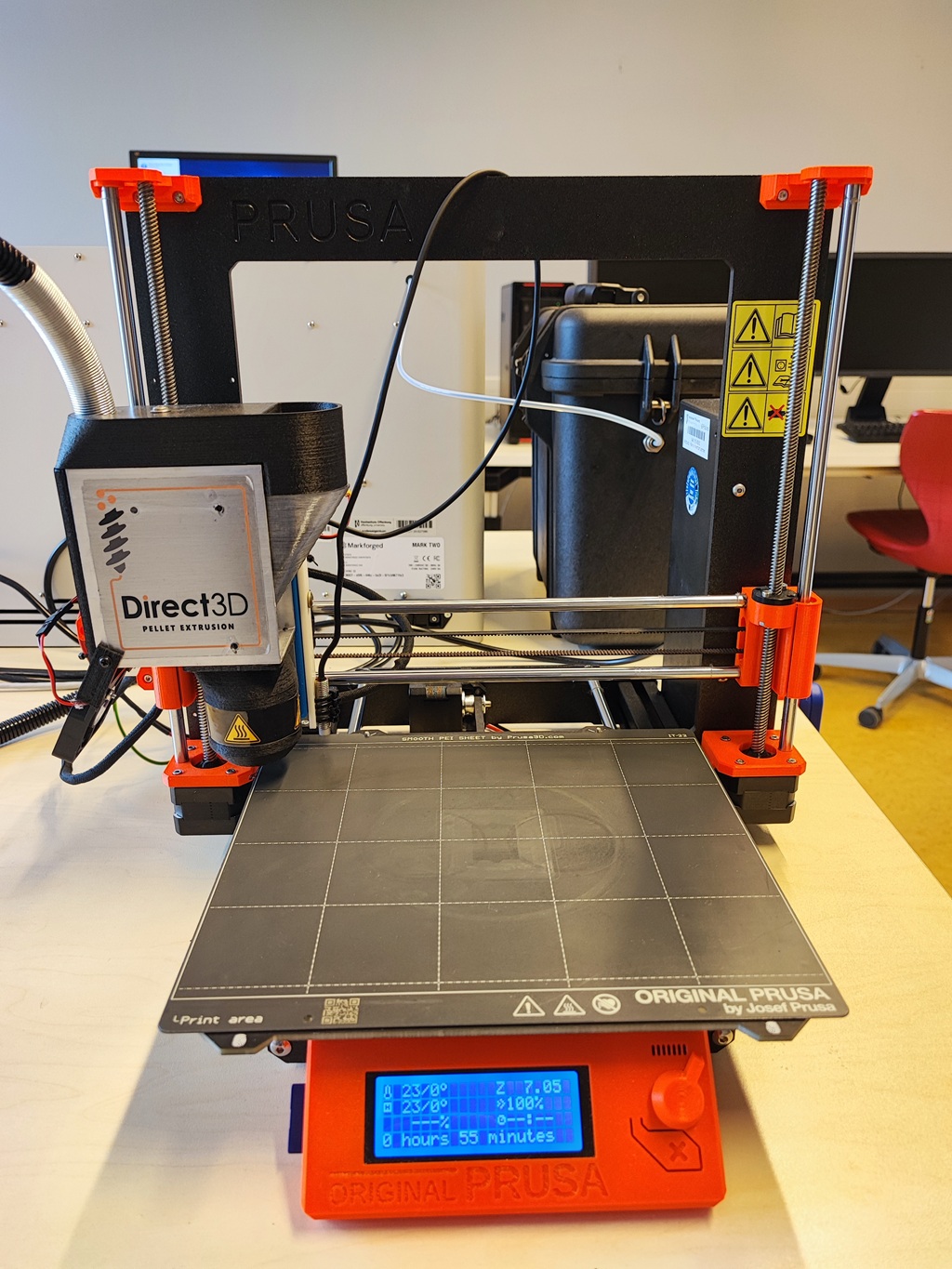

- i3 MK3S from Prusa Research + multimaterial unit + Pellet/Granule Extruder from Direct3D

- Pam o2 MC from Pollen

- SL1 from Prusa Research + curing station

- Phrozen Sonic Mini 8k

- X1E from Bambu Lab + Automatic Material System (AMS)

- 3D scanner Artec Eva, Artec Spider

- Memmert Heating cabinet/Drying cabinet

Software:

- CATIA V5 from Dassult Systèmes

- Netfabb Professional

- Artec Studio 18

- Grab CAD Print

- Different slicing softwares

Bachelor:

- Computer Aided Engineering 1 - Design and additive manufacturing of a simple application example (JetMobil)

- Innovative product development - supervision during project work

- Supervision and implementation of seminar papers and theses

Master:

- Computer Aided Engineering 2 - Design of a gearbox and additive manufacturing of individual components in the laboratory

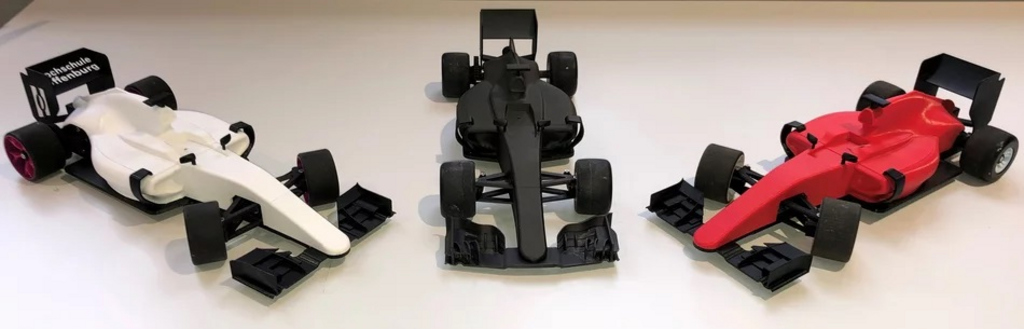

- Workshop Rapid Prototyping - additive manufacturing and methodical further development of RC cars in selected areas and disciplines (compulsory elective subject for Master's students from all faculties)

- Workshop Additive Manufacturing - development, design and production of a soft robot in the form of a bionic muscle using 4D printing of magnetically responsive elastomers (compulsory elective subject for Master's students of all faculties)

- Supervision and implementation of seminar papers and theses

If you are interested in 3D printing, whether internally or externally, please contact us!

In a joint consultation, we will be happy to discuss your request and the further procedure.

The contact details of our lab's contact persons can be found in the right column.

We are looking forward to a joint cooperation!