Part of the 4D Printing Research Group at Offenburg University of Applied Sciences visited the leading international trade fair FormNext in Frankfurt to learn about the latest developments in additive manufacturing and establish contacts with leading companies and research institutions worldwide. FormNext is considered the most important trade fair for additive manufacturing and industrial production technologies and celebrated its tenth anniversary this year with a total of 803 exhibitors. For the research group, the visit was a valuable opportunity to gain insights into current trends, innovative materials, and future technologies that are relevant to their own research work.

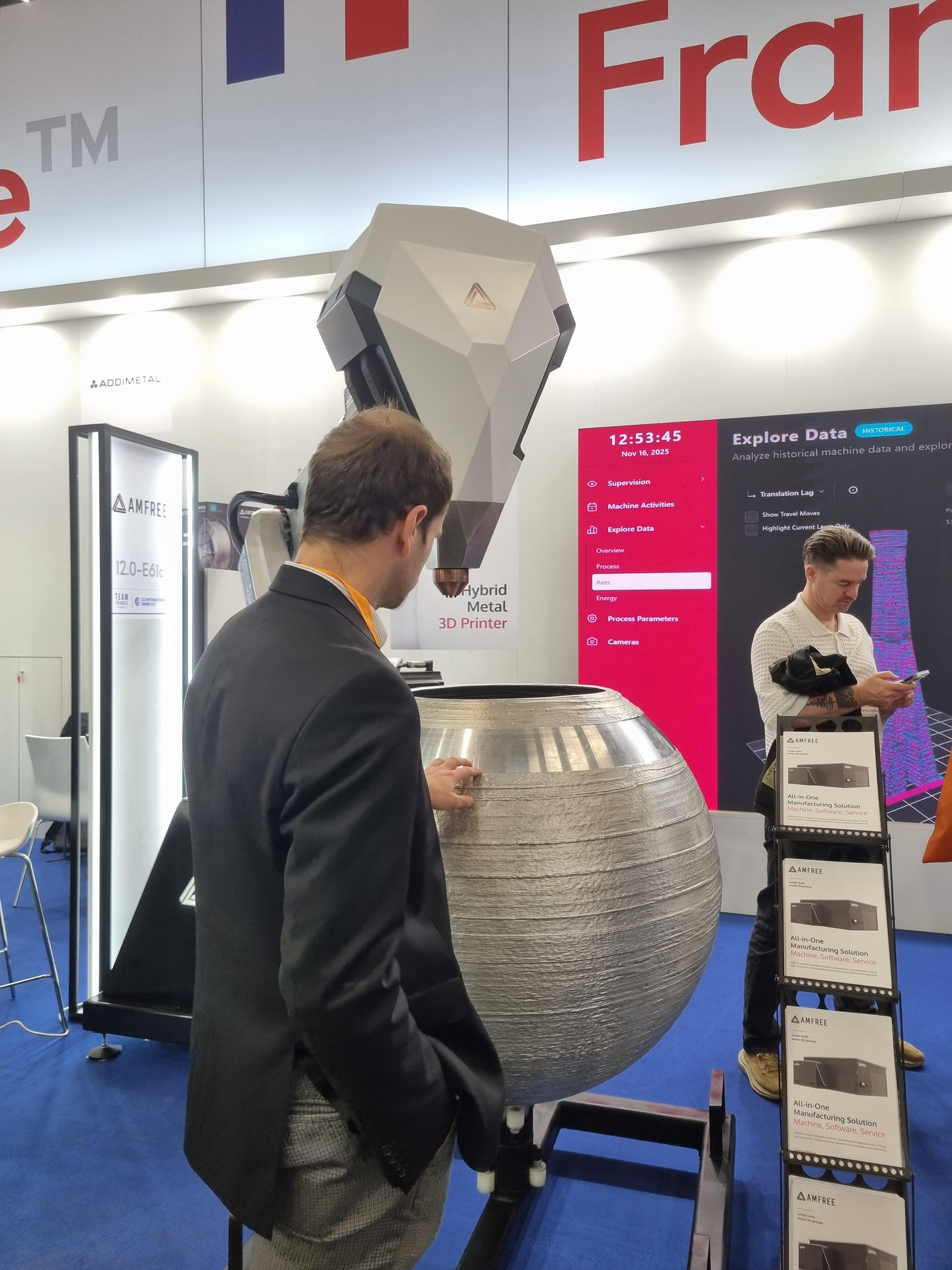

This year's trade fair focused in particular on the economic role of additive manufacturing and its concrete added value for numerous industrial sectors. The exhibition showcased particularly practical applications that have been developed in recent years. The field of metal-based additive manufacturing was well represented. In addition the field of pellet 3D printing also had a stronger presence this year. This means that a wide range of injection molding materials can be processed for 3D printing, even without the addition of additives. Increasing industrialization, which is also characterized by robot-assisted processes, was a key theme at this year's event.

Visiting the FormNext trade fair also provided an excellent opportunity to exchange ideas with international partners from industry and science. This included maintaining contacts with scientists from the Portuguese 4D printing industry. Daniel Kehret, who recently received the Young Researcher Award at Pro DPM 2025 in Leiria, was able to meet up again with fellow scientists from the Politecnico de Leiria whom he had met at the conference.

In addition to visiting the trade fair, the focus was on discussions with technology providers, material manufacturers, and scientific institutions. The 4D printing research group established contacts that could enable future collaborations or joint projects in the field of magnetic-responsive elastomer (MRE) processing. Visiting FormNext 2025 was an important step for the 4D printing research group at Offenburg University of Applied Sciences in identifying new technical trends at an early stage, deepening their knowledge, and strengthening networking within the specialist community.